Categories

Categories

- Home

- Tecnotion: Direct Drive Motor Technology

- Iron Core Linear Motors

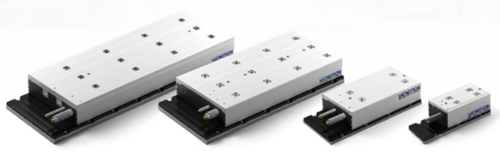

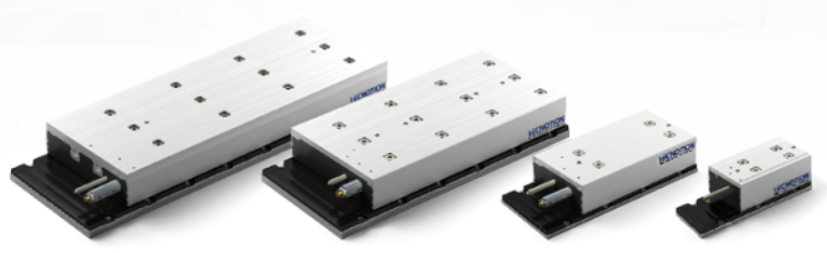

Iron Core Linear Motors

Product Description

Designed and constructed with an iron core, these linear motors offer extremely high continuous force for their size, starting at 60N for the small TM, all the way up to 3000N for the water cooled TBW powerhouse. Peak forces are even higher, reaching up to 6000N.

All this raw power comes in a surprisingly compact package. Its small footprint, modular design and high force density enable very fleible application designs. The ability to string multiple motors together, either in series or parallel, widens its range of applications even further.

Analog Hall Module

Linear motors can be positioned extremely accurately by using optical encoders and rulers. If this is not required this expensive setup can be replaced by an Analog Hall module. This module uses the magnet track, as opposed to the ruler, as the linear scale. It can be easily mounted on our iron core motors and communicates with practically all standard servo controllers. The Analog Hall module requires a standard 5Vdc power supply.

Linear motors can be positioned extremely accurately by using optical encoders and rulers. If this is not required this expensive setup can be replaced by an Analog Hall module. This module uses the magnet track, as opposed to the ruler, as the linear scale. It can be easily mounted on our iron core motors and communicates with practically all standard servo controllers. The Analog Hall module requires a standard 5Vdc power supply.

Digital Hall Module

For commutation, we have an optional digital Hall module that can be used with our entire range of linear motors. Its sensors provide 3 digital outputs, each phase shifted 120 degrees, to determine the electrical angle between coils and magnets. If you do not use a controller that allows you to commutate within the servo drive, this module can be a cost-effective alternative. The digital Hall module requires a 4.5 to 28Vdc power supply.

For commutation, we have an optional digital Hall module that can be used with our entire range of linear motors. Its sensors provide 3 digital outputs, each phase shifted 120 degrees, to determine the electrical angle between coils and magnets. If you do not use a controller that allows you to commutate within the servo drive, this module can be a cost-effective alternative. The digital Hall module requires a 4.5 to 28Vdc power supply.

Iron Core downloads

Download TECNOTION Iron Core catalogue, leaflets, manual and CAD files below

- Additional Products - Leaflet (pdf)

- Analog Hall - Leaflet (pdf)

- Catalogue Iron Core / Ironless Motors (pdf)

- TB series - Leaflet (pdf)

- TBW series - Leaflet (pdf)

- TL series - Leaflet (pdf)

- TM 3Z - Leaflet (pdf)

- TM 6Z - Leaflet (pdf)

- TM serie - Leaflet (pdf)

- Analog Hall - CAD file (pdf)

- Dig.Hall - CAD file (pdf)

- Digital Hall - Manual (pdf)

- Iron Core Motors - Manual (pdf)

- Simulationtool - Iron Core & Ironless (zip)

- TB serie - CAD files (zip)

- TBW serie - CAD files (zip)

- TL series - CAD files (zip)

- TM series - CAD files (zip)

Loading... Please wait...

Loading... Please wait...